Pulp Lid for Disposable Bagasse Fiber Packing Box

description1

description2

Specification

Size (mm) |

234.6*234.6*14 |

Weight (g) |

20 |

Carton Size (cm) |

54.5*41.5*24.5 |

Packing (pcs) |

50*4 |

Raw Material |

Sugarcane Bagasse Pulp |

Product Service |

Free sample with postage at your own expense |

Pulp molding is also called (plant) fiber molding, which is the process of making the fiber in the pulp into a wet blank, and then drying and solidifing the wet blank. Plant fiber in the suck-filter forming molds first through suck-filter forming, made into wet blank, The wet blank is sent into the heating molds heated to a certain temperature, clamp the hot pressure mold and dry the wet blank, to make the molded fiber (pulp) products of various shapes.

Molded fiber food packaging mainly include pulp molded tableware, molded fiber plates and bowls,molded fiber meal boxes, molded fiber instant noodle bowls, molded pulp dishes, molded fiber cups, molded fiber clean dishes, etc.; Molded pulp industrial packages products mainly include the shock-proof internal packaging of electronic products, medical instruments, gifts and other industrial products. In recent years, these molded pulp industrial packages products have become more sophisticated and delicate.

The degradable molded fiber products are made of annual herb fiber pulp (bagasse, reed, wheat straw, bamboo, etc.) as raw materials, adding additives, after special treatment, heating and pressing the pulp on the mold.

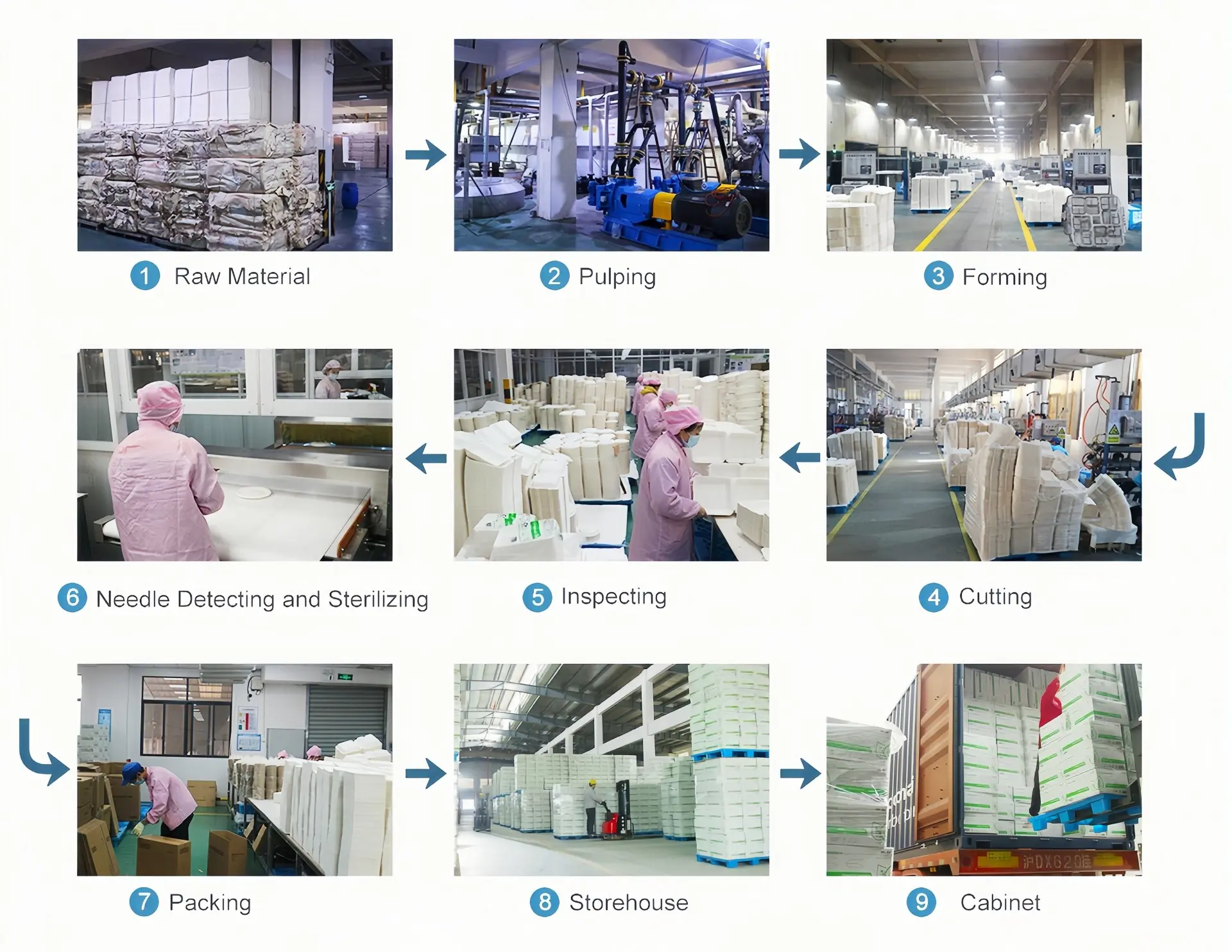

Production Process